What is CNC Milling?

The world of machining is vast, with numerous methods to choose from, such as CNC milling. We’ll explore why CNC milling is essential for specific manufacturing processes, learn some of its basics, and identify some typical applications in different industries. You’ll see why CNC milling is the perfect blend of precision, speed, and versatility.

Understanding CNC Milling

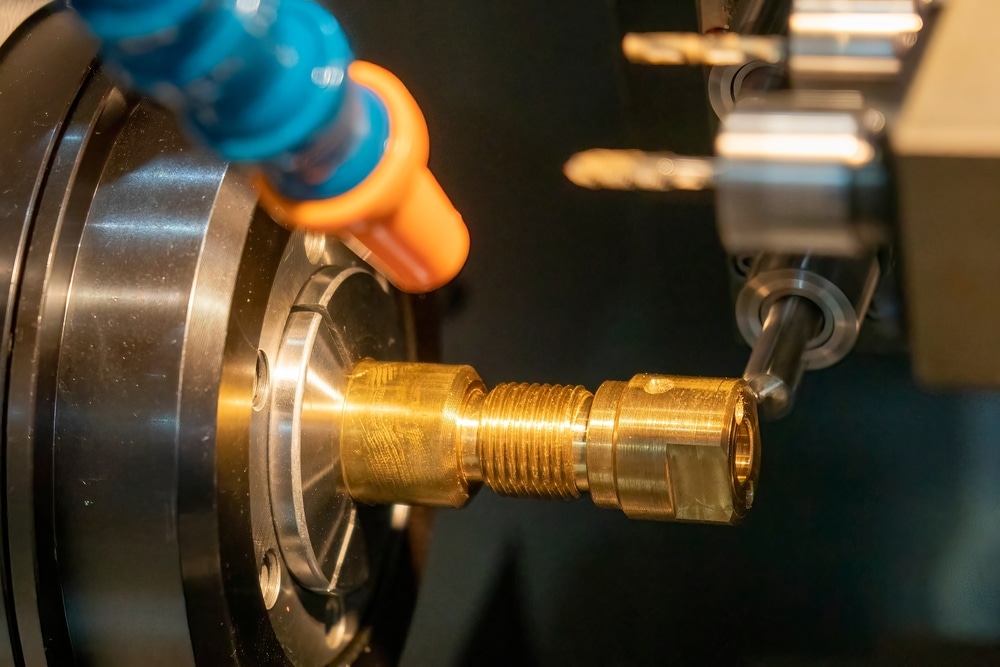

CNC milling is a modern machining technique that uses Computer Numerical Controls to speed up the manufacturing process for quicker turnaround times and more accurate outputs. It employs multi-cutting tools to remove material from a workpiece to achieve a particular form. The workpiece may be metal, plastic, wood, or glass.

The cutting tool is mounted on a rotating spindle, while the workpiece is securely mounted on a table. Cutting-edge CNC milling machines have five or more axes of motion to achieve more intricate designs and shapes.

CNC milling can machine components of extremely tight tolerances. It can handle small to large production runs and ensures high precision in its outcomes. Due to its versatility, it can create parts and components for various applications. Depending on the required features, different operations are used.

Key Operations in CNC Milling

The versatility of CNC milling is demonstrated through its various operations, essential for achieving different design specifications:

- Face Milling: The cutting tool’s axis is perpendicular to the workpiece. This technique is known for high-quality finishes.

- Plain Milling: Used for milling plain horizontal surfaces. With this technique, the tool is parallel to the workpiece surface.

- Form Milling: Suitable for irregular surfaces and complex contours.

- Angular Milling: Involves milling surfaces at an angle, using single-angular or double-angular cutters.

- End Milling: The milling cutter’s teeth are on the periphery and face, suitable for shallow, flat surfaces and notches.

- Drilling, Reaming, and Tapping: Employing drills, reamers, and taps for creating holes, finishing hole walls, and cutting internal threads respectively.

The Advantages of CNC Milling

CNC milling offers significant advantages:

- Precision and Consistency: Ideal for projects demanding exact specifications.

- Efficiency: The machine’s ability to carry multiple tools enhances manufacturing speed.

- Endurance: Designed to operate for long periods, reducing the need for constant human intervention.

Industries Leveraging CNC Milling

Various industries rely on CNC milling for its precision and flexibility:

- Aerospace: For durable, lightweight parts that ensure safety and performance.

- Automotive: Many automotive parts are created through CNC milling, such as gear boxes, cylinder heads and mounting bases.

- Medical: For precise manufacturing of prosthetics, surgical tools, and implants.

- Defense: Ensuring uniformity in weapon parts, from prototypes to mass production.

Partnering with McCormick Industries

CNC milling has become widely used across multiple industries. Using the correct operation, your project’s specific needs are met, creating excellent results that will drive success to your business.

If you’re looking for a reputable manufacturer who can deliver reliable CNC milling services, McCormick Industries is a company you can trust. We can collaborate to create a cost-effective solution tailored to your needs. Learn more about our capabilities by calling us today for more information or contact us for a quote.

What makes a Swiss lathe different?

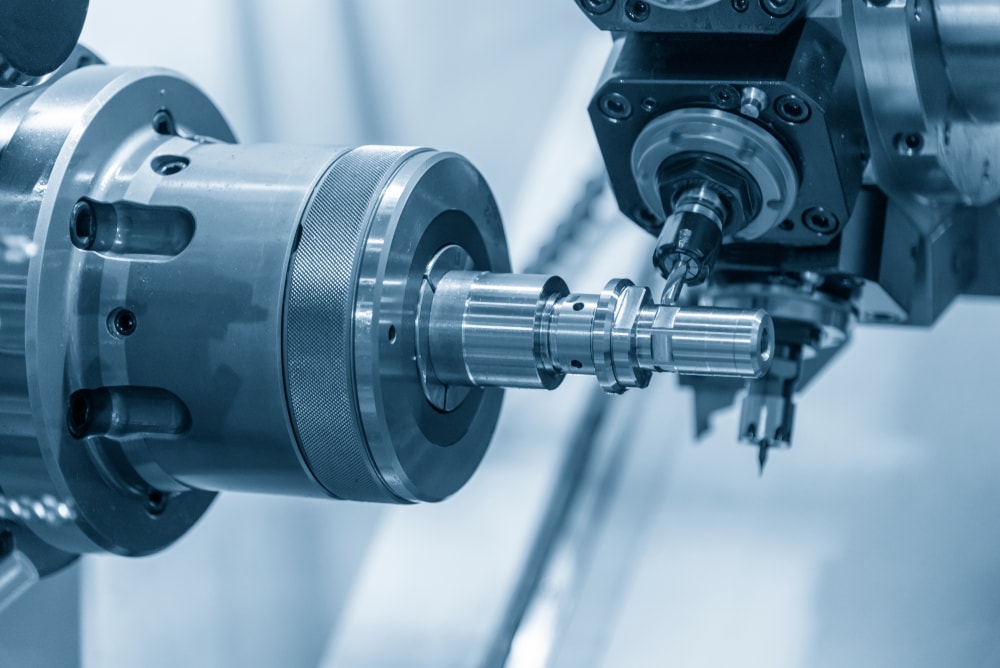

A lathe is a machine tool that uses rotational force to shape metal or other materials. There are many types of lathes, but the Swiss lathe is extremely interesting. What makes the Swiss lathe unique? Let’s take a closer look.

Swiss lathes are known for their precision and accuracy

Swiss lathes are ideal for machining small, intricate parts. Swiss lathes use a collet and guide bushing to hold the stock material in place as it is turned or milled. The guide bushing provides additional assistance for the material, allowing for more precise cuts.

Swiss lathes can create thinner and more precise cuts than other types of lathes. They also have a live tooling feature, which allows for different milling and drilling bits. Finally, Swiss lathes are known for their rigidity. The material is cut very close to where the bar is supported by the guide bushing. This means they are less likely to vibrate during operation, resulting in more accurate parts with tight tolerances.

Swiss lathes are used in various manufacturing industries

Swiss lathes are often used in manufacturing because of their precision and accuracy. They can be used to create various objects commonly used in the following industries:

- The oil and gas industry uses nozzles, pins, washers, and fasteners made from swiss lathes.

- In the medical industry, swiss lathes are used to create small, delicate parts for implants and other devices.

- The aerospace industry uses swiss lathes to create precision parts for aircraft engines, missiles, and rockets.

- The automotive industry uses swiss lathes to create engine parts and other components.

Swiss lathe vs. CNC lathe

One of the key differences between a Swiss lathe and a CNC lathe is the guide bushing. Swiss lathes usually come with more tooling choices than other types of lathes. This means you can make more products with a Swiss lathe.

On the other hand, CNC lathes are known for their speed and efficiency. They can be programmed to quickly create large quantities of parts with little to no human intervention. CNC lathes are often used in critical industries, such as the automotive industry, where speed and efficiency are crucial.

Today’s Machining World also notes that the headstock on a Swiss machine moves. This happens very precisely back and forth. The following are some of the features that distinguish a Swiss lathe from other types of lathes:

- Flexibility: Swiss lathes are also very versatile. They can be used to create a variety of different objects.

- Industry Standard: Swiss lathes are often used in the manufacturing industry. You’ll use the same machine in many factories worldwide if you purchase a Swiss lathe.

Swiss precision for your manufacturing needs

Utilizing a Swiss lathe is an excellent option for those in the manufacturing industry with a need to create small, slender components with tight tolerances.

Please contact us if you would like to learn more about our Swiss lathe services and the other services we provide. McCormick Industries would be happy to provide you with a quote for your next project.

What Is the Difference Between CNC Turning and Milling?

Computer numerical control (CNC) machining is a manufacturing process that uses computerized controllers to operate machine tools. This technology has been around for decades and has been used extensively in the aerospace, medical, industrial, and electrochemical industries.

CNC milling and turning are two of the most common processes in CNC machining. Though both involve the use of computer-controlled machinery, there are several key differences between the two.

Here, we will take a closer look at those differences to help you better understand which process is right for your project.

What is CNC turning?

CNC turning is a machining process that uses computer numerical control (CNC) to rotate a workpiece while it is held in a chuck. This rotating motion, combined with the movements of the cutting tool, allows for precise and repeatable machining of cylindrical parts.

CNC turning can be used to create parts of various shapes and sizes, from small components to large-scale workpieces. The process is well suited for high-volume production and one-off parts, making it a versatile manufacturing solution.

CNC turning is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. The process can be performed on various materials, including metals, plastics, and composites.

Let’s dive into the benefits of using CNC lathes for turned parts.

The benefits of CNC turning

The benefits of CNC turning are numerous and can be extremely helpful in a variety of manufacturing settings. The most obvious benefits are the following:

- CNC turning can significantly increase the speed and accuracy of production.

- CNC turning can produce parts with very tight tolerances.

- CNC turning can create complex shapes that would be difficult or impossible to create using other methods.

- CNC turning is a very fast and efficient way to produce parts in large quantities.

- CNC turning can be used to produce parts from a variety of materials, including metals, plastics, and composites.

- CNC turning is a very versatile manufacturing process that can be used to create a wide variety of parts and products.

Another significant benefit of CNC turning is that it can help to reduce the amount of waste produced during manufacturing. This is because CNC machines can be programmed to produce parts with very specific dimensions, which reduces the need for material trimming or other forms of waste.

Overall, the benefits of CNC turning can be beneficial for a variety of manufacturing businesses. CNC machines can help to improve the speed and accuracy of production while also reducing waste. These benefits can ultimately lead to increased efficiency and profitability for a business.

Now, let’s talk about CNC milling.

What is CNC milling?

CNC milling is a machining process that uses computer-controlled rotary cutting tools to remove material from a workpiece. Tool paths are created from a CAD file and uploaded to the CNC machine, which then controls the motion of the tool to remove material and create the desired shape. The process can be performed on various materials, including metals, plastics, and composites.

CNC milling is a versatile machining process that can be used to produce a variety of parts with a high degree of accuracy. CNC milling can also be used to produce parts with a variety of surface finishes. It is commonly used in the aerospace, automotive, medical, and energy industries.

So why should you use CNC milling?

The benefits of CNC milling

CNC milling offers a number of benefits over traditional machining methods. The following are some of the most notable benefits of CNC milling:

- CNC milling allows for precise and repeatable machining of parts.

- CNC milling can be used to create complex shapes and geometries.

- CNC milling can be used to create parts with a high degree of dimensional accuracy.

- CNC milling can be used to create parts with a smooth surface finish.

- CNC milling can be used to create parts with various material properties.

- CNC milling can be used to create parts with different thicknesses and sizes.

Overall, CNC milling is a popular manufacturing process due to its many benefits, including increased accuracy and repeatability, increased productivity, increased versatility, and reduced waste. This technology can be used to create a wide variety of parts and products, from simple prototypes to complex end-use components.

Final thoughts: Difference between CNC turning and milling

CNC milling and turning are both processes that are used to create parts and products from raw materials. Both processes can be used to create a variety of different shapes and sizes, and both require the use of a CNC machine.

However, there are some key differences between CNC milling and turning. CNC milling involves rotating cutting tools to remove material from a stationary workpiece, which is typically square or rectangular. CNC turning utilizes a lathe to rotate primarily round bar stock while using cutting tools to remove material.

Ultimately, the decision of which process to use depends on your project’s specific requirements. CNC milling and turning can produce high-quality parts and products.

What Is Swiss Machining?

History of Swiss Machining

The Swiss Screw machine, developed in Switzerland in the 19th century, has made its mark as the premier lathe when producing small, complex parts. Different from conventional lathes, Swiss machines move bar stock through a guide bushing using a sliding headstock. The headstock moves the material forward or backward, exposing only the portion being machined.

The Swiss Screw machine, developed in Switzerland in the 19th century, has made its mark as the premier lathe when producing small, complex parts. Different from conventional lathes, Swiss machines move bar stock through a guide bushing using a sliding headstock. The headstock moves the material forward or backward, exposing only the portion being machined.

The utilization of a gang tool post and guide bushing provides close proximity of the cutting tool to the material, minimizing part deflection and delivering an increase in precision while holding tight tolerances. As with other machining processes like mills and lathes, Swiss CAM automatic machines have led to CNC Swiss machines for better automation.

Swiss Precision Machining Services

What are the Advantages of Swiss Precision Machining?

Greater Productivity

Current Swiss Screw machines use a computer numerical control (CNC) unit to process parts to meet specifications by following a coded, programmed instruction without a manual operator. With room for 20+ tools and the ability to perform multiple operations simultaneously, complex parts can be completed in one operation on the machine—as opposed to traditional lathes requiring multiple operations. CNC Swiss machining also offers capabilities for secondary processes, such as slotting, milling, cross-drilling, and cross-tapping, eliminating the need for additional machining once the turned parts come off the machine.

Higher Versatility

Swiss machines usually work in diameters of 1 ¼” and under, with the majority of work smaller than ¾”, but they also excel at producing parts with lengths much greater than diameter. The ability to produce long, slender parts while reducing deflection, is a key benefit of running those higher length-to-diameter ratio parts on a Swiss machine.

Larger Cost Savings

Swiss machines accommodate smaller workpieces, which enables industry professionals to use smaller bar stock. The lower cost of these materials translates to lower overall production costs without sacrificing product quality. Swiss machines achieve greater precision and accuracy, even in complex and intricate part designs. With good quality bar stock, swiss machines allow for tight tolerances, often eliminating the need for outside grinding service. Additionally, once a machine has been setup, some parts allow for unmanned runtime, leading to an increase in labor efficiency in the shop while cutting down lead times for customers.

Applications of Swiss Machines

Originally created to manufacture screws for the watchmaking industry, Swiss machines have evolved their reach across industries. While these machines still manufacture parts for high-end watches, they also can be found machining screws to serve a wide range of industries including:

Originally created to manufacture screws for the watchmaking industry, Swiss machines have evolved their reach across industries. While these machines still manufacture parts for high-end watches, they also can be found machining screws to serve a wide range of industries including:

- Industrial components

- Medical machined components

- Components for musical instruments

- Parts for aerospace and defense industries

With the ability to machine many types of metals and hold tight dimensional tolerances, there is little that Swiss machines cannot do when it comes to machining small parts.

What Materials Are Used in Swiss Machining?

Swiss machining can employ a variety of materials depending on the required specifications of the components. These range from common materials like steel to exotic alloys:

- Aluminum

- Brass

- Bronze

- Carbon Steel

- Copper

- Plastics

- Stainless Steel

- Steel

- Tool Steel

- Titanium

- Exotic Alloys

Contact the Swiss Machining Experts at McCormick Industries Today

Swiss machining is a viable manufacturing method for many industrial applications. Compared to traditional turning processes, it offers greater precision, productivity, versatility, and cost-effectiveness.

If you are looking for a partner for your next Swiss machining project, turn to the experts at McCormick Industries. Equipped with over two decades of industry experience and a modern machining facility, we have the knowledge, skills, and tools to fulfill any CNC Swiss precision turning need. To learn more about our capabilities, visit our CNC Swiss Turning services page or contact us today. For pricing details, request a quote.