What is Precision Machining?

Leave a Comment

Precision machining has become essential to the manufacturing sector. This subtractive manufacturing process often pairs expert designers and engineers with the most advanced equipment available to create parts and components with extremely intricate or complex geometries. Precision machining is essential for the creation of many critical parts used in numerous industries, including the aerospace, electronics, and medical device machining industries.

Methods of Precision Machining

Precision machining relies on the use of advanced, computerized machine tools to achieve demanding tolerances and create complex geometric cuts with a high degree of repeatability and accuracy. This can be achieved through the use of automated computer numerical control (CNC) machine tools.

CNC Machining

Designers create digital design files using computer-aided design (CAD) software, which is then translated into a computer-aided manufacturing (CAM) file that gives instructions to the CNC machining equipment about which tools and processes to use. CNC mills and CNC lathes are the most common types of automated machine tools, though state-of-the-art CNC machining centers can often perform the functions of both. Tasks performed during CNC machining could include milling, , turning, drilling, tapping, boring, and more.

Designers create digital design files using computer-aided design (CAD) software, which is then translated into a computer-aided manufacturing (CAM) file that gives instructions to the CNC machining equipment about which tools and processes to use. CNC mills and CNC lathes are the most common types of automated machine tools, though state-of-the-art CNC machining centers can often perform the functions of both. Tasks performed during CNC machining could include milling, , turning, drilling, tapping, boring, and more.

Multi-Axis CNC Machining

The machine tools typically used for high-precision CNC machining have what is known as multi-axis capabilities. With multi-axis machining, processes can be performed simultaneously and save substantial setup time, leaving less room for human error that may occur during part repositioning.

Most standard CNC tools work on at least 3 axes, allowing work on the X, Y, and Z linear axes at the same time. Multi axis precision machining, however, typically relies on 4 to 5-axis machining for its efficiency and superior capabilities. With the addition of the A/C and B axes, 4 to 5-axis CNC machining offers greater precision and detail and can access the workpiece from virtually any direction.

Generally, 4 to 5-axis machines are the bare minimum for precision machining. Multi-axis machines are available with up to 9 axes of motion, providing the ultimate in precision machining. Multi-axis CNC machining is frequently used for medical CNC machining as well as aerospace, automotive parts and components for power generation.

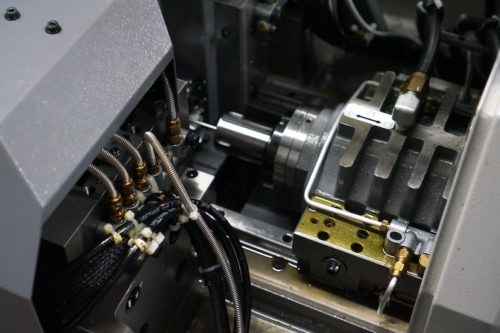

Swiss Machining

Swiss machining is a specific type of CNC machining which creates parts by bringing the stock to the tool rather than the other way around. They provide a great degree of precision among the various types of CNC machining. Extremely accurate Swiss machining can achieve tolerances within ±0.0001 inches.

Once tooling is set up, Swiss machine tools can often run unattended for long periods of time, facilitating greater production volumes with less required labor. The superior precision of Swiss machining is extremely well-suited to producing components and parts for robotics, custom pins, surgical tools, aerospace, custom ferrules, electronics, and precision tooling, among others.

Learn More About the Advantages of Swiss Machining

Applications of Precision Machining

Precision machining produces parts to a much more exacting standard than baseline CNC machining. It is an excellent solution to meet stringent project requirements, such as:

Precision machining produces parts to a much more exacting standard than baseline CNC machining. It is an excellent solution to meet stringent project requirements, such as:

- Tight tolerances. With the right equipment available, precision machining can produce parts with tolerances as small as ±0.0001″.

- Repeatability. Successful precision machining means that parts must be able to be machined to the same tight tolerances repeatably from part to part.

- Volume. Precision machining practices can handle virtually any production volume requirement ranging from prototypes to high-volume production runs and blanket orders.

Suitable Materials for Precision Machining

Precision machining produces high-quality, exacting parts from a wide variety of materials. Frequent materials used for precision machining include:

- Aluminum

- Brass

- Bronze

- Carbon steel

- Copper

- Plastics

- Stainless steel

- Steel

- Titanium

- Tool steel

- Exotic alloys

Precision Machining From McCormick Industries

At McCormick Industries, we specialize in precision machining using our state-of-the-art equipment. Our expertise and experience leave us especially well-prepared to manufacture small and complex parts. Request a quote today to see how our precision machining capabilities can serve your project, or contact us with any questions you may have.