What is CNC Milling?

Leave a CommentThe world of machining is vast, with numerous methods to choose from, such as CNC milling. We’ll explore why CNC milling is essential for specific manufacturing processes, learn some of its basics, and identify some typical applications in different industries. You’ll see why CNC milling is the perfect blend of precision, speed, and versatility.

Understanding CNC Milling

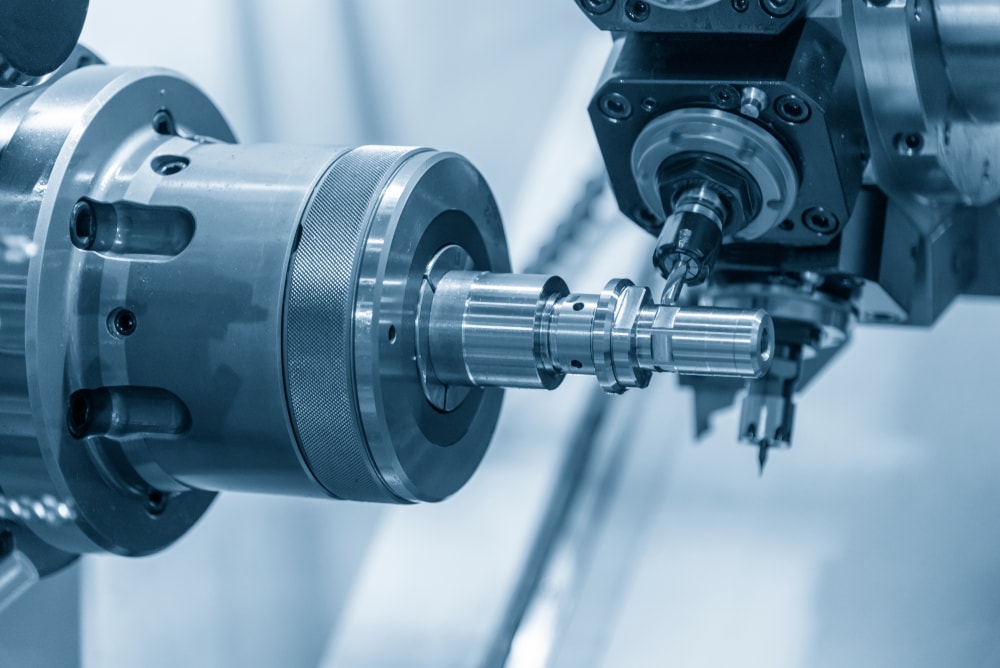

CNC milling is a modern machining technique that uses Computer Numerical Controls to speed up the manufacturing process for quicker turnaround times and more accurate outputs. It employs multi-cutting tools to remove material from a workpiece to achieve a particular form. The workpiece may be metal, plastic, wood, or glass.

The cutting tool is mounted on a rotating spindle, while the workpiece is securely mounted on a table. Cutting-edge CNC milling machines have five or more axes of motion to achieve more intricate designs and shapes.

CNC milling can machine components of extremely tight tolerances. It can handle small to large production runs and ensures high precision in its outcomes. Due to its versatility, it can create parts and components for various applications. Depending on the required features, different operations are used.

Key Operations in CNC Milling

The versatility of CNC milling is demonstrated through its various operations, essential for achieving different design specifications:

- Face Milling: The cutting tool’s axis is perpendicular to the workpiece. This technique is known for high-quality finishes.

- Plain Milling: Used for milling plain horizontal surfaces. With this technique, the tool is parallel to the workpiece surface.

- Form Milling: Suitable for irregular surfaces and complex contours.

- Angular Milling: Involves milling surfaces at an angle, using single-angular or double-angular cutters.

- End Milling: The milling cutter’s teeth are on the periphery and face, suitable for shallow, flat surfaces and notches.

- Drilling, Reaming, and Tapping: Employing drills, reamers, and taps for creating holes, finishing hole walls, and cutting internal threads respectively.

The Advantages of CNC Milling

CNC milling offers significant advantages:

- Precision and Consistency: Ideal for projects demanding exact specifications.

- Efficiency: The machine’s ability to carry multiple tools enhances manufacturing speed.

- Endurance: Designed to operate for long periods, reducing the need for constant human intervention.

Industries Leveraging CNC Milling

Various industries rely on CNC milling for its precision and flexibility:

- Aerospace: For durable, lightweight parts that ensure safety and performance.

- Automotive: Many automotive parts are created through CNC milling, such as gear boxes, cylinder heads and mounting bases.

- Medical: For precise manufacturing of prosthetics, surgical tools, and implants.

- Defense: Ensuring uniformity in weapon parts, from prototypes to mass production.

Partnering with McCormick Industries

CNC milling has become widely used across multiple industries. Using the correct operation, your project’s specific needs are met, creating excellent results that will drive success to your business.

If you’re looking for a reputable manufacturer who can deliver reliable CNC milling services, McCormick Industries is a company you can trust. We can collaborate to create a cost-effective solution tailored to your needs. Learn more about our capabilities by calling us today for more information or contact us for a quote.

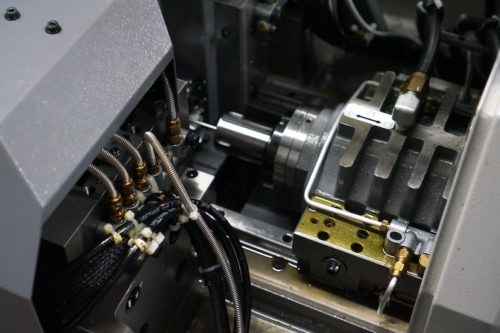

The Swiss Screw machine, developed in Switzerland in the 19th century, has made its mark as the premier lathe when producing small, complex parts. Different from conventional lathes, Swiss machines move bar stock through a guide bushing using a sliding headstock. The headstock moves the material forward or backward, exposing only the portion being machined.

The Swiss Screw machine, developed in Switzerland in the 19th century, has made its mark as the premier lathe when producing small, complex parts. Different from conventional lathes, Swiss machines move bar stock through a guide bushing using a sliding headstock. The headstock moves the material forward or backward, exposing only the portion being machined.